Chinese | English

Skype: zhiguang.wu

Email:15230713671@163.com

Address: North Mengcun Industrial Park, Mengcun Hui Autonomous County, Cangzhou, Hebei.

The composition of the elbow machine and the material of the

The composition of the elbow machine and the material of the main push system

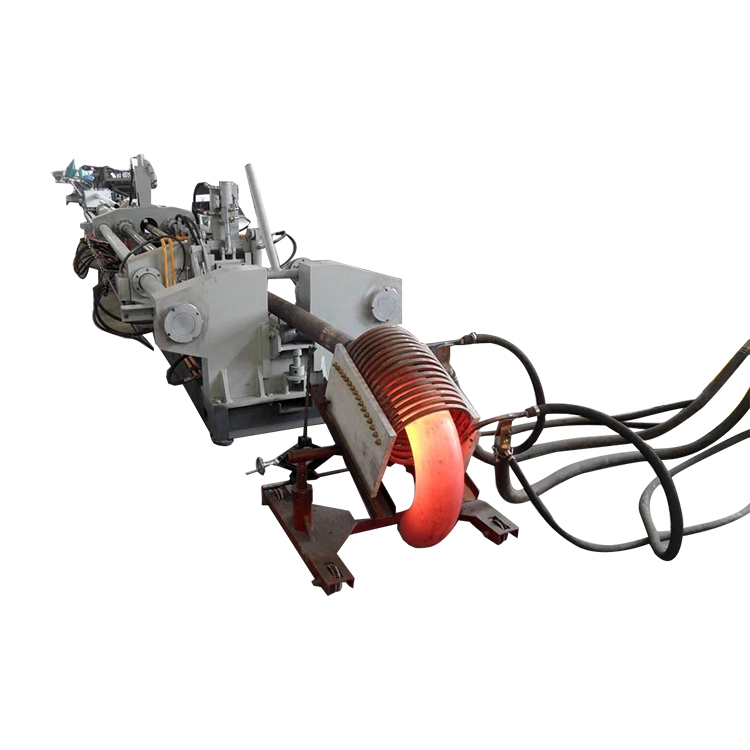

Elbow machine is composed of five parts, including frame body, main oil cylinder, push-made oil cylinder, hydraulic station, electrical appliances and other main components. Machine operating mode USES the manual hydraulic valve, the working principle of the cavity ensure pipe diameter would be able to take shape, with multiple diameter of steel ball to push system, to ensure that in the process of pushing into shape tube buckling image, a steel ball synchronous driving system, make the elbow after molding shape ovality range + / - 0.2 or so, after molding cavity mould, artificial remove the elbow, In this process, a blank of the elbow is completed, and then the elbow is put on the beveling machine for both ends of the elbow.

Metal elbow push forming machine

Metal stainless steel elbow cold push molding machine, mechanical design and production of elbow machine high efficiency, is more than 2 times the speed of traditional equipment, according to different pipe wall thickness demoulding speed can be adjusted.

Medium frequency elbow machine diameter 21-1620mm, wall thickness 3-120mm, material steel pipe length 3-24m, medium frequency heating push machine mold (core head), heating coil, ordered by the user separately. Medium frequency heating push machine made by the user alone. Medium frequency heating push system of low price, quality assurance, high production efficiency.

The main push pump is selected according to the push elbow and the gate mandrel is heated to the working temperature. The push speed is adjustable and pushed to the midpoint of the push machine. The hydraulic gate is automatically stopped. Note: The main push pump can be used at the same time, generally only one can be used. Can also be used to retreat without stopping. 2. The receding pump can not be used at the same time, only one can be started, and the other can be used for backup. Feeding pump can only be used when feeding. The steady pressure of the hydraulic system of the main oil pump and the hydraulic system of the auxiliary cylinder shall be set as. The stroke switch is installed at both ends of the stroke of the push machine, and the actual stroke should be less than the large stroke, that is, the allowance left at both ends of the active push plate from the actual end point, so as not to run the cylinder piston.