Chinese | English

Skype: zhiguang.wu

Email:15230713671@163.com

Address: North Mengcun Industrial Park, Mengcun Hui Autonomous County, Cangzhou, Hebei.

Introduction of pipe fitting machinery

Introduction of pipe fitting machinery

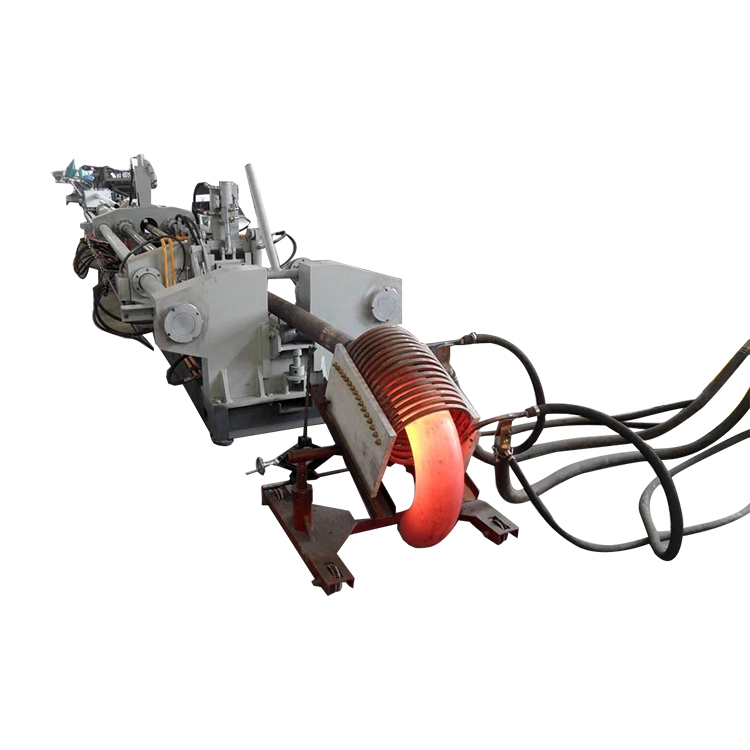

Pipe fitting machinery includes elbow machine, pipe bending machine, tee machine, pipe expanding machine and so on.The mechanical part of the pipe bending fittings is equipped with four major mechanisms, which are power source mechanism, clamping and fixing mechanism, bending radius adjusting mechanism and pushing mechanism.

Pipe fitting machinery including pipe bender;We can do both the bend diameter from 21 to 1620mm and the wall thickness from 3 to 100mm.Pipe fitting machinery also includes hydraulic medium frequency pipe bender, hydraulic medium frequency pipe bender can be used for carbon steel, alloy, stainless steel, any material of steel pipe.Therefore, the mechanical properties of the pipe fittings are good, the wear resistance is good, the mechanical production efficiency of the pipe fittings is high, the fault is less and the life is long.

What matters should be paid attention to during the operation of pipe fitting equipment

Operators work closely with the feed restrictor during the operation of pipe fitting equipment to ensure that all partners are announcing bending signals.It is necessary to compaction the sheet material when bending, so that the pipe fitting equipment can prevent the sheet material from warping and wounding when bending, and it is necessary to cut off the power supply when adjusting the sheet material pressing die. The pipe fitting equipment is suitable for stopping the operation.When changing the opening of the lower die, no material is allowed to contact with the lower die. When the machine tool is operating, the back of the machine tool is not allowed to stand.Prevent pressing and folding sheet material at one end alone.If the workpiece or mold is found to be incorrect during operation, stop to proofread. The large bend elbow push mechanism should be proofread by hand to prevent hand injury.To avoid damage to the machine tool, it is necessary to prevent the folding of super-thick iron plate or hardened steel plate, alloy steel, square steel and the sheet metal which exceeds the performance of the sheet bending machine and the cylinder elbow pushing machine.The staff should check the coincidence degree of the upper and lower molds, and whether the instructions of the pressure gauge conform to the regulations.Abnormal immediately shut down, check the original and timely cleaning.

Before the pipe fitting equipment is turned off, wooden blocks shall be placed under the lower die of both sides of the oil cylinder to lower the upper slide onto the wooden blocks.Exit the control system program first, then plug the load power supply.

Aocheng machinery is a professional production of pipe fittings equipment company.Since its establishment, we adhere to the principle of honesty, steady management, get the trust of domestic customers, to the company to establish a good corporate image.

1989-1988.