Chinese | English

Skype: zhiguang.wu

Email:15230713671@163.com

Address: North Mengcun Industrial Park, Mengcun Hui Autonomous County, Cangzhou, Hebei.

Inspection and composition of hydraulic elbow machine before

Inspection and composition of hydraulic elbow machine before operation

Before working, the hydraulic elbow machine needs to check whether the electrical switch, travel limit switch is safe and reliable, whether the operation is flexible, whether the safety protection device is safe and reliable.Check whether the hydraulic oil on the side of the hydraulic elbow machine has reached the red line limit.Check whether the pressure regulating valve on the oil pressure circuit of the hydraulic elbow machine is in a state of no load. The block of the hydraulic elbow machine must touch the rear limit.Confirm the hydraulic elbow machine written on the work instruction sheet is consistent with the content of the work.After checking the mould of the hydraulic elbow machine and all the above required to check the car is normal, our operator can start to work.

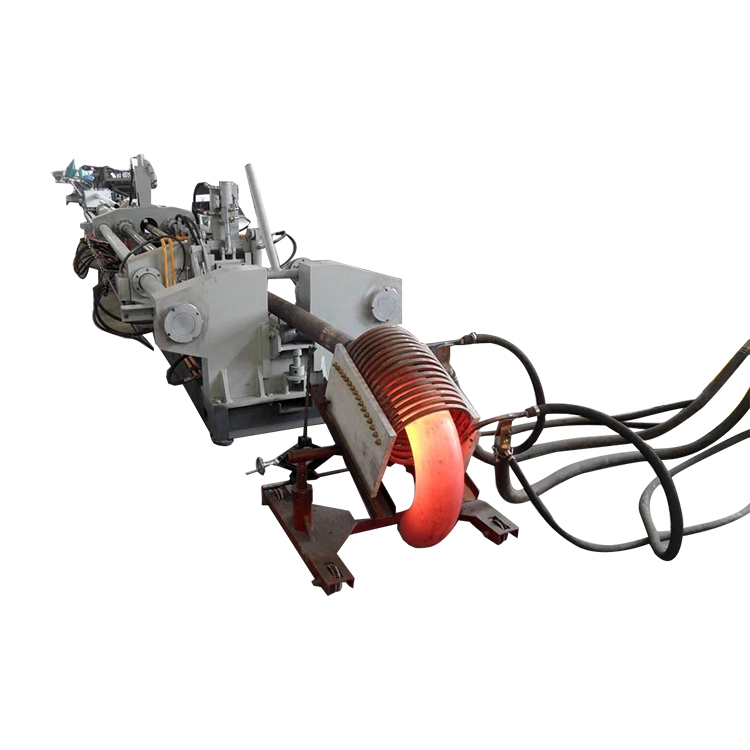

The hydraulic elbow machine mainly includes: the frame, the main cylinder support plate (including the main cylinder), the movable push plate, the front support plate, the semi-automatic feeding mechanism, the intermediate frequency coil adjustment frame (including the intermediate frequency heating coil), the intermediate frequency power supply, the electrical control system and so on.

Medium frequency heating push machine is divided into a push type (push elbow) and two (three) push type (push expansion pipe) two forms.Hydraulic secondary propulsion pipe making machine, the total stroke of standard type is 10.5-12.5 meters, we can also lengthen the total stroke according to customer requirements.

Components of the device:

The working principle of the equipment:

Equipment repair and maintenance

1, check all parts of the fastener, make it in a tight state.

2. The joints of the hydraulic pump station are equipped with oil-resistant rubber sealing rings. If the sealing rings are damaged or leaked, they should be replaced in time.

3. If the forward and backward failure is found, first check whether the solenoid valve is acting normally, and then check the sequence valve 6X3,

Relief valve YF - L20H4 or one-way unloading valve 4HD3 has no impurity stuck phenomenon.(This phenomenon generally occurs when the device is in use

Prone to).If there is a dead phenomenon, open it with gasoline or diesel oil, clean it, and then reinstall it.

4. Clean the oil tank and filter the hydraulic oil once within 1 to 2 months after the equipment begins to use.

5. When cleaning the oil tank, the oil inlet filter of each pump should be cleaned.

1986-1969.